WHAT'S NEW

Škoda Auto Volkswagen India Growth Story continues with cumulative sales of 145,713 units (Domestic + Export) in 2023

Škoda Auto India to bring back Superb luxury sedan to cater to increased customer demand

Škoda Auto India Enhances Digitalisation Strategy To Fuel New Era Of Growth In India

Škoda Auto India Announces The Next Leg Of The Name Your Škoda Campaign For Its All-New Compact SUV

Škoda Auto announces all-new compact SUV for India

Škoda Auto Volkswagen India Awarded Platinum Rating For Green Manufacturing Warehouse, Setting New Industry Standards

Škoda Auto India Launches Slavia Style Edition In Exclusive Numbers

Leadership change at Škoda Auto Volkswagen India: Jan Bures to head Sales and Marketing

Škoda Auto Volkswagen India to showcase future-ready technologies at Bharat Mobility Expo 2024

Škoda Auto India registers sales of over 1,00,000 cars across two years

Launch of Lamborghini Revuelto in India: The First Super Sports V12 Hybrid HPEV

Škoda Auto India Launches Elegance Editions In All - New Deep Black Colour For The Kushaq And Slavia

Škoda Auto Volkswagen India Inaugurates Parts Expedition Centre in Pune, to Facilitate Parts Exports to ASEAN Region

Esperienza Giro India 2023: Royal Adventure Amidst 60 Years of Excellence

Audi India Registers Robust Growth of 88% In The First Nine Months of 2023

Vietnam Launch: Škoda Auto Celebrates Key Internationalisation Milestone

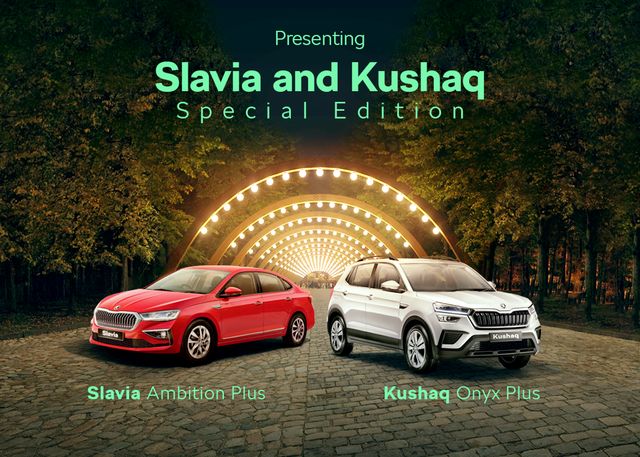

Škoda Auto India Rings In The Festivities With New Variants Of The Kushaq And Slavia

Škoda Auto India Launches Exchange Carnival For August 2023

Škoda Auto Volkswagen India Crosses 600,000 Car Exports Milestone

Škoda Auto India Announces Monsoon Service Campaign

Škoda Auto India Launches New Brand Strategy Based On The New Brand Philosophy - ‘Let’s Explore’

Škoda Kushaq Gets All-New Matte Edition

Lamborghini India Delivers 150th Huracán In The Country

Škoda Auto Enters The Realm Of NFTs With Škodaverse India

Škoda Auto India Further Enhances Supplies Of Flagship Kodiaq To Quicken Delivery Time

Democratizing Its Performance Line, Volkswagen India Announces Prices Across The New Variants And The GT Edge Limited Collection On Taigun And Virtus

Audi India Announces Industry First Initiative For EV Owners - Introduces ‘Charge my Audi’ On The ‘myAudiConnect’ App

Škoda Auto Focuses On Safety To Further Grow The Brand In India

Rising Demand Sees Škoda Auto India Increase Allocations For Kodiaq 4X4

Škoda Auto Volkswagen India Launches its First-Ever Student Car Project in India

Invest in Our Planet: Škoda Auto Volkswagen India generates 3800+ pledges in line with the theme of Earth Day 2023

Škoda Auto India Builds On India 2.0 Success With Continued Product Offensive Strategy

Škoda Slavia and Volkswagen Virtus set new safety standards in the sedan segment with a 5-Star rating in Global NCAP crash tests

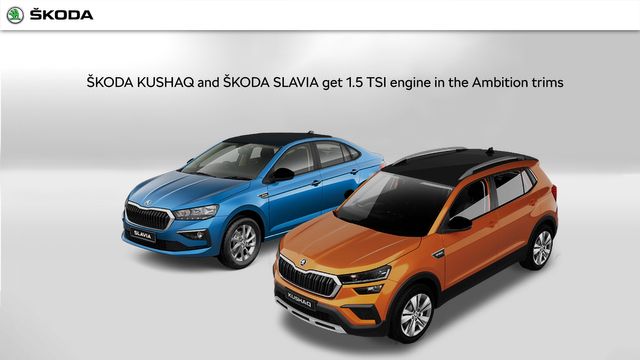

ŠKODA AUTO India Expands 1.5 TSI Range Based On Demand From Driving Enthusiasts

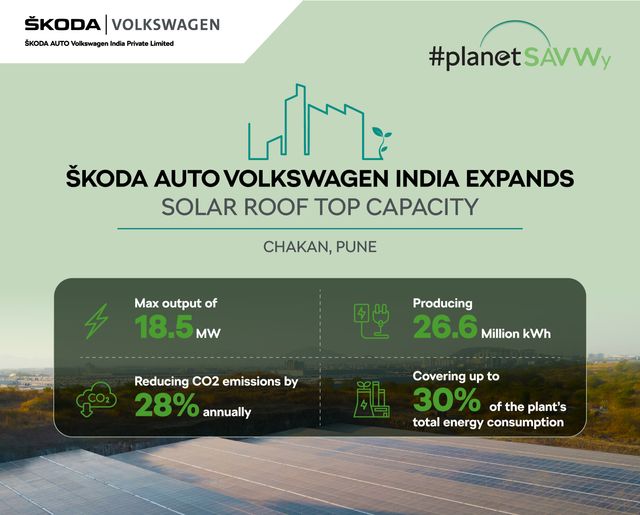

Škoda Auto Volkswagen India increases its solar rooftop capacity to 18.5 MW

Audi India launches top-of-the-line new Audi Q3 Sportback

E20-compliant ŠKODA KUSHAQ and Volkswagen TAIGUN flagged off by PM Shri Narendra Modi at the Alternative Fuels Based Vehicles Rally

Porsche India celebrates 2022 as its best sales year ever, 64 per cent up on 2021

ŠKODA AUTO India rewards Service Challenge 2022 winners

ŠKODA AUTO India looks to accelerate growth through 2023

ŠKODA AUTO Volkswagen India domestic sales zoom past 100,000 units in 2022

Audi India registers 27% growth in 2022

Volkswagen India registers a 58% annual growth in its sales performance in 2022

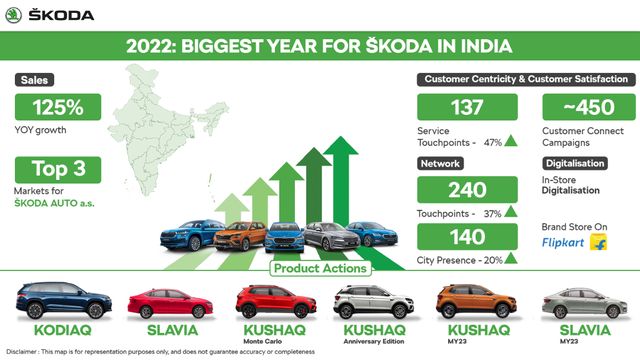

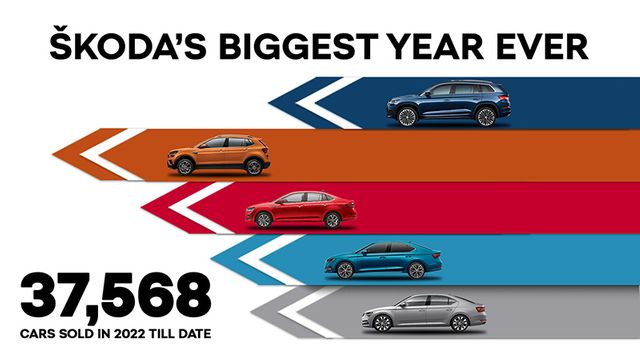

ŠKODA AUTO India records 2022 as the ‘Biggest Year’ in India

50+ start-ups take up the hackathon challenge in ŠKODA AUTO DigiLab’s i-mobilothon

Audi India announces price increase across model range

ŠKODA AUTO Volkswagen India’s Aurangabad Plant switches to 100% Green Energy

Audi India launches the Audi Q5 special edition

Porsche India exceeds its previous best-ever annual result by the third quarter

ŠKODA KUSHAQ and Volkswagen TAIGUN achieve a 5-star rating in Global NCAP crash tests

Porsche 911 GT3 RS completes the ‘ring in 6:49.328 minutes

ŠKODA AUTO poised to enter Vietnamese market

Audi India registers robust growth of 29% year-to-date 2022

ŠKODA AUTO Volkswagen India commences exports of the ŠKODA KUSHAQ from India

Audi India introduces new colors and features on the Audi A4

ŠKODA AUTO Volkswagen India commences production of ŠKODA KUSHAQ LHD

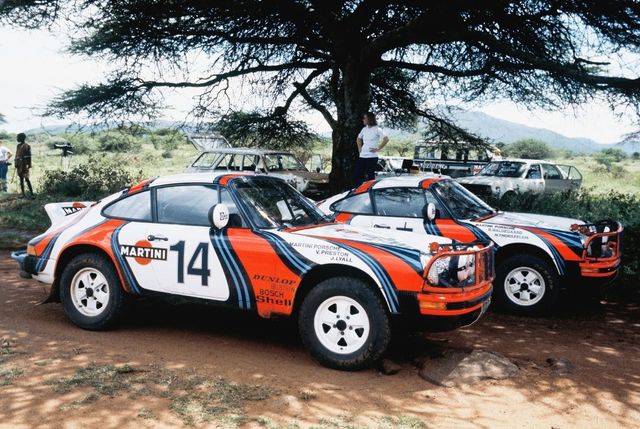

Icons of Porsche returns in November 2022 with a safari showcase and featuring a new model regional premiere

ŠKODA AUTO Volkswagen India starts exporting Volkswagen Virtus

Audi India bolsters EV charging infrastructure – completes installation of 100+ chargers across 60+ cities in India

K2K: a Porsche Taycan traverses India

Volkswagen launches First Anniversary Edition of Taigun, marking one stellar year of the SUVW in India

ŠKODA AUTO Records Biggest Year in India

Audi India launches new Audi Q3

Porsche India highlights personalisation options in a rare showcase of Porsche Exclusive Manufaktur program

Lamborghini Huracán Tecnica Debuts in India

Petr Šolc appointed Director – Sales & Marketing of ŠKODA AUTO India

Volkswagen India commences exclusive previews of its much-awaited SUVW – the Taigun

Audi India opens bookings for the New Audi Q3 Announces variants and features

Lamborghini India delivers 200th Urus in the country

Purpose-built for performance: the new Porsche 911 GT3 RS

Volkswagen India celebrates 10 years of association with Sundaram Motors in Chennai

2023 model year software status for all Taycan variants

Porsche India records its best ever half year sales result

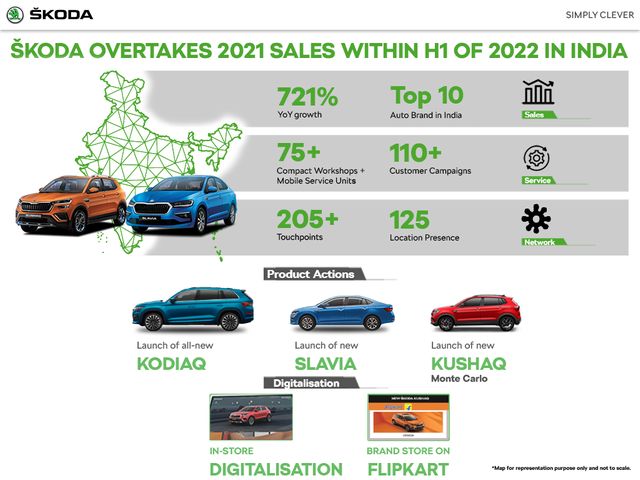

ŠKODA AUTO Volkswagen India records best-ever half-yearly (H1) sales Clocks 200% growth in H1 2022

Nalin Jain appointed as the Executive Director – Finance and IT at ŠKODA AUTO Volkswagen India Private Limited

Striking outside. A world of its own inside: Audi launches the new Audi A8 L in India

Lamborghini unveils the Aventador Ultimae Coupé in India Limited to only 350 units

Lamborghini India delivers another Ultimae Roadster in India

ŠKODA AUTO India shatters all records in June and H1 2022

Volkswagen India announces a strong sales performance by doubling its sales volume in H1 2022 with the Taigun and new Virtus

ŠKODA AUTO Volkswagen India trains Mechatronics professionals

Volkswagen India goes ‘Big by delivery’ by organising mega delivery programs for the newly launched Virtus across India

Lamborghini Aventador Ultimae Roadster comes to India. It takes time to become timeless.

Volkswagen launches its striking, exhilarating and German-engineered new Virtus at INR 11.21 lakh for its Indian customers

Porsche India launches Porsche Approved business

Porsche India celebrates strong Q1 with 22-percent more new car deliveries

ŠKODA AUTO Volkswagen India commences third shift at Pune facility

Porsche India appoints new dealers in Bengaluru and Chennai

ŠKODA AUTO Volkswagen India drives past new milestone; 1.5 Million cars produced from India facilities

ŠKODA AUTO Volkswagen India Strengthens Leadership Team

ŠKODA AUTO Volkswagen India marks a new milestone in its INDIA 2.0 journey

ŠKODA AUTO Volkswagen India marks a new milestone in its INDIA 2.0 journey

Porsche India records its best business performance since 2014 and its highest ever order intake

Piyush Arora appointed as the new Managing Director of ŠKODA AUTO Volkswagen India Private Limited

Volkswagen announces the start of production of the exciting new Tiguan in India

Audi India beings local production of its legendary Audi Q7 at the SAVWIPL plant in Aurangabad

Amaan Shaikh declared Best Apprentice from India at Volkswagen Group’s Global ‘Best Apprentice Award 2021

Volkswagen India launches the exciting new Tiguan at an introductory price of INR 31.99 lakh (ex-showroom)

Audi India introduces A4 Premium to celebrate a successful 2021

Audi India launches the Audi Q5 in a striking new avatar

Audi India expands pre-owned car business - opens Audi Approved: plus facility in Bhubaneshwar

The all-new premium midsize sedan: ŠKODA SLAVIA

Presenting the all-new ŠKODA SLAVIA

Audi India announces complimentary Road Side Assistance for customers impacted by the Chennai floods

ŠKODA Releases Interior Sketches of the new ŠKODA SLAVIA

Volkswagen Taigun receives an overwhelming response from customers across India; drives 50% growth for the brand in October

ŠKODA AUTO showcases first sketches of the new SLAVIA

Audi India expands retail presence; inaugurates new showroom Audi Delhi West

Volkswagen India expands its network with a new touchpoint in Delhi East

The bestseller gets sportier: Audi India opens bookings for the Audi Q5

Announcing the winner of the “Camouflae with ŠKODA” contest

New ŠKODA AUTO premium mid size sedan will be called SLAVIA

Audi India expands pre-owned car business - opens Audi Approved: plus facility in Ludhiana

ŠKODA AUTO India introduces the new RAPID Matte Edition

Under the skin of the Mission R

Volkswagen India launches its much-anticipated SUVW Taigun at an introductory price of INR 10.49 lakh (ex-showroom, India)

Audi India amps up electric vehicle drive with the launch of India’s first electric super cars - Audi e-tron GT and Audi RS e-tron GT

ŠKODA crosses the 10,000-bookings mark with the KUSHAQ

ŠKODA AUTO India announces 'Compact Workshops'

Volkswagen India enhances its partnership with ORIX; Introduces subscription based car ownership model

ŠKODA AUTO India sales up by 282% in August

"Camouflage with ŠKODA”: Shortlisted designs announced

Volkswagen India announces start of production and pre-bookings open for the much-awaited SUVW - the Taigun

Audi India Launches its Strong and Striking Audi RS 5 Sportback in India

ŠKODA AUTO India strengthens presence in Madhya Pradesh

ŠKODA AUTO India Announces a Unique Design Contest

ŠKODA AUTO to be present in more than 100 cities in India

Audi plugs in to electric mobility – Launches 3 electric SUVs – Audi e-tron 50, Audi e-tron 55 and Audi e-tron Sportback 55

Volkswagen implements New Brand Design and Logo across the network in India

Audi India offers a myriad of digital solutions and initiatives for Audi e-tron and Audi e-tron Sportback customers

ŠKODA AUTO strengthens ‘Peace of Mind’ campaign

Audi India announces curated ownership plans for Audi e-tron and Audi e-tron Sport back customers

Audi India to offer multiple variants of the Audi e-tron in India

Audi India opens bookings for its all electric SUVs – the Audi e-tron and Audi e-tron Sport back

ŠKODA KUSHAQ launched in India starting at a ₹ 10.49 lacs

Sarah Simpson becomes Chief Executive Officer of Porsche Cars Great Britain

The ‘Indian Pre-owned Car Market Study’ commissioned by Volkswagen India to Frost & Sullivan revealed that by FY2025 organized platforms will contribute 45% to the total pre-owned car market

Dynamic, elegant, timeless, and emotive: The all-new ŠKODA OCTAVIA launched in India

ŠKODA KUSHAQ: Start of Production

Unveiling the biggest product line-up under its SUVW strategy, Volkswagen India commences bookings for award-winning SUV T-Roc

Volkswagen India extends service period and warranty on products until 30th June 2021

Audi India announces extension on Standard Warranty, Extended Warranty & Service Plans

With ‘Accessibility’ at its core, Volkswagen India announces its robust Service and TCO initiatives

New arrival at Volkswagen India: The Taigun is on its way

ŠKODA AUTO India commences production of the all new OCTAVIA

Volkswagen India announces the biggest product lineup under its SUVW Strategy

Designed to turn heads. Engineered to thrill

Audi India opens new state-of-the-art service facility in Bhopal

Power Day: Volkswagen presents technology roadmap for batteries and charging up to 2030

Volkswagen India and Frost & Sullivan collaborate on developing ‘Indian Pre-owned Car Market Study’

ŠKODA AUTO India expands its footprint in South India with its first dealership in Puducherry

With a focus on accessibility and enhancing customer connect, Volkswagen India is now available on WhatsApp for Business

ŠKODA AUTO India inaugurates its maiden 3S dealership facility in North East with SSB Automobiles

ŠKODA KUSHAQ: Design sketches offer a preview of the new SUV for the Indian market

Volkswagen India launches the Turbo edition of the Polo & Vento

ŠKODA AUTO India further expands its footprint in Karnataka with PPS Motors

ŠKODA KUSHAQ: Made for the World, in India

The refreshed ŠKODA SUPERB: Contemporary, Elegant, and Luxurious